the Polyfloss

An insulation made from recycled plastic

The Waste for Warmth partnership is developing and testing a new approach to shelter winterisation by making tent insulation in the field. The insulation is made from recycled plastic, using a technology called Polyfloss that resembles candy-floss in appearance.

1.7

R value

The thermal resistance of the floss material makes it a good insulation material.

10

kg/hour

is the quantity of plastic the machine can turn into floss in one hour.

Our machine

The Polyfloss Factory technology can transform plastic waste into fibers, through hot centrifugation. These fibers have a wide range of applications, from insulation and packaging, to textiles and molded plastic pieces.

The machine can operate in areas where management of plastic is an issue, to transform those waste into ressources.

The polyfloss technology can be use to setup small local recycling facilities using local plastic waste as raw material.

The machine can process shredded PP and PET.

Waste

Plastic waste is an abundant material in refugee camps across the world, as a byproduct of the humanitarian responses. Upcycling local waste gives discarded and single use plastics materials a new life as insulation products.

Work

Setting up local production offers work opportunities for displaced people to generate income. Localized responses also alleviate the need for shipment of material from afar at great cost and environmental impact.

Warmth

Improvised as well as planned shelters for displaced people lack long-term provisions for winter conditions. Living conditions are made worse by the need to burn unclean fuels for heating. Solutions to retrofit existing tents with insulation material are cost efficient and reduces the need for fuel.

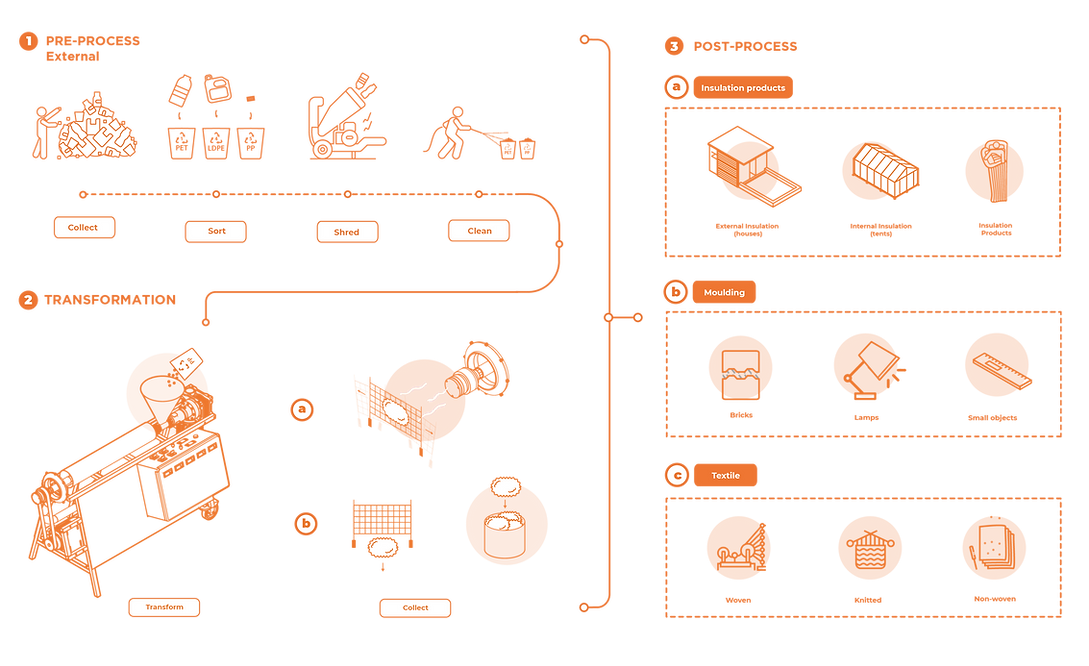

The process

These are the main steps in transforming waste plastics into new products, using the Polyfloss technology.

Video by Sahaya Hazir - Field Ready.